Why Side Stream Filter?

|

|

|

|

|

|

Save Energy Save Water! |

|

Use filtration to minimize suspended solids in the system will reduce potential fouling that may results corrosion and loss of efficiency at heat exchanger. |

|

Optimize the effectiveness of water treatment programs |

|

Reduce biofouling and health

risks |

|

Save Water |

|

Minimize

maintenance & downtime |

|

Maximize equipment life |

|

ROI typically 8-12 months |

Why To Use A 0.45 Micron High-Efficiency Vortisand Side Stream Filtration System? Why To Use A 0.45 Micron High-Efficiency Vortisand Side Stream Filtration System?

| ōAll heating and cooling systems should be thoroughly cleaned. The greatest enemies to seal assemblies of any configuration are magnetic iron, silica, and other solids in suspension, especially if their size is in the 1 to 10-micron rangeö |

Paul J. Mallar, Manager

ITT Bell & Gossett,

Maintaining Heating and Cooling System Pumps,

Maintenance Technology Magazine, May 1988.

|

Chilled Water Filtration - Iron Removal

|

|

|

43 ppm Iron removed after only 56 days Improved Chemical Efficiency |

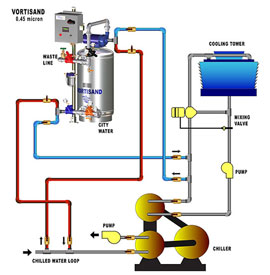

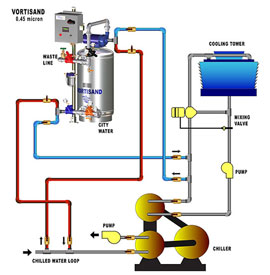

How To Install Vortisand Filtration System?

|

|

|

|

|

|

Alternate Water

Loop - Filter

can be used on both

open and closed loop

systems. Primary

filtration on

cooling tower loop

and secondary

(alternate)

filtration on closed

loop when required. |

|

|

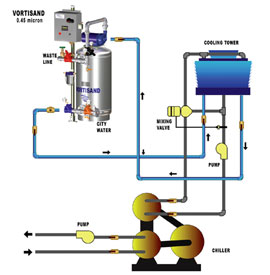

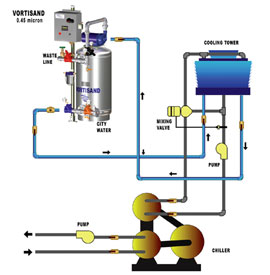

Basin to Basin -

Sump water

intake and return.

Our high efficiency

design reduces the

need for sweeper

piping in tower

sumps. |

|

|

Why To Use A 0.45 Micron High-Efficiency Vortisand Side Stream Filtration System?

Why To Use A 0.45 Micron High-Efficiency Vortisand Side Stream Filtration System?